Equipment

Armoured Face Conveyor (Face Coal Haulage)

Once the coal is cut, it has to be removed from the

face to the maingate, so some form of coal haulage system is required. In early

hand-working days, belt conveyors were used, but these are not amenable to high

production rates as the whole conveyor had to be moved sideways to advance the

face.

The major development, apart from self-advancing

supports, allowing high production longwalls to evolve was the "Armoured

Face Conveyor or AFC"

which was originally developed in Germany and was frequently (less so nowadays)

referred to as a "Panzer" conveyor.

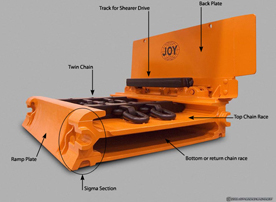

Essentially an AFC is a one-sided trough scraper

conveyor, the second side of the trough being formed by the coal face. Cut coal

falls into this trough which has an endless chain with scraper flights attached

running along the base plate and returning below the base plate in an enclosed lower

section or "race". The

coal is dragged along the base plate by the flights.

Early AFC's had two outboard chains, one running each

side of the base plate with flights connecting them. Later developments saw the

two outboard chains replaced by a single centre chain with flights cantilevered

each side. With increasing longwall size, the single centre chain has now

become a double or triple centre chain on almost all longwalls.

The outer ends of the AFC flights (or outer chains on

old AFC's) are kept in place on the base by a channel section lip at each side

of the base. A similar arrangement for the return chain below the base leads to

this part of the AFC being known as the "Sigma Section" because of its shape.

The chain is driven, via sprockets, by electric motors

at both ends of the face (maingate and tailgate, although earlier AFC's were

driven by maingate drives only). These drives must sit in line with the face at

each end and the size of drive(s) required is often the limiting factor on the

practical face length (along with AFC chain strength and size). To accommodate

the sprockets and shafts, specially shaped AFC sections have to be used at each

end of the AFC to raise the chain path.

To provide a degree of horizontal and vertical

articulation in the AFC along the face, the AFC consists of many individual

sections joined together with flexible couplings, these sections being known as

"pans". The length of each

pan is normally the same as the chock width, so the face has the same number of

chocks as pans over most of its length (some special arrangements are required

at the face ends). The flexibility allows the AFC pans to be moved in differing

amounts along the face so that short lengths can be pushed towards the face

forming a bend or "snake".

To provide a degree of horizontal and vertical

articulation in the AFC along the face, the AFC consists of many individual

sections joined together with flexible couplings, these sections being known as

"pans". The length of each

pan is normally the same as the chock width, so the face has the same number of

chocks as pans over most of its length (some special arrangements are required

at the face ends). The flexibility allows the AFC pans to be moved in differing

amounts along the face so that short lengths can be pushed towards the face

forming a bend or "snake".

The connection between pans is by

means of dumbbell shaped bars (known as "dog bones") slotted quite loosely into brackets

mounted on the back plates and the front of each pan.

The connection between pans is by

means of dumbbell shaped bars (known as "dog bones") slotted quite loosely into brackets

mounted on the back plates and the front of each pan.

Pans with a removable section in the base plate, known

as "inspection pans",

are spaced along the face, to allow access to the bottom race for cleaning or

repair purposes as well as inspection.

In order to move the AFC forward after the shearer

advances along the face, hydraulic cylinders mounted horizontally on the

support bases are attached to the steel (or goaf) side of the AFC trough,

referred to as the "back plate" or "spill plate".

These cylinders are double acting, and besides being able to push sections of

the AFC forward, are utilized to pull forward or advance the supports, once

they are lowered from the roof.

The main and tailgate drives are mounted on base

plates which have to be rigid (the drive trains can only have minimal

flexibility), so support attachments at the face ends are generally via rigid

structures and the drives are pushed forward by several chocks at the same

time.

Coal is actually cut in front of the AFC, so a lot of

the coal initially sits on the base of the cut section and does not fall

directly onto the AFC. This coal is lifted onto the AFC as it is pushed

forward. Because it is necessary to cut the maximum amount of coal on each web,

it is important that this coal is able to be cleaned up as the AFC advances and

not left on the floor, thereby preventing the AFC being pushed right to the

solid coal. For this reason the front edge or toe of the pan is normally built

in a wedge shape, to ramp up the coal at the face and assist in the clean up

(hence the toe of the pan is sometimes called the "ramp plate"). In the past small ploughs were sometimes

fitted to the front of pans and dragged along the length of the face to improve

the loading (commonly referred to as "activated ramp plates"). Improved toe plate design on modern

longwalls has obviated the need for theses activated ramp plates.

Apart from the AFC's primary function of removing the

cut coal from the face, its structure is used for other purposes:

-

The edges of the base

are used as tracks for the coal cutting machines (shearers) to run on

-

Tracks or chains

utilized for haulage of the shearer are mounted on the AFC in most cases, and

-

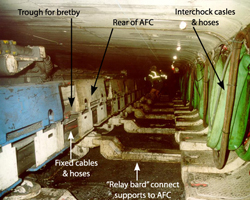

Troughs and attachments

are mounted on the back plates to carry fixed and trailing cables and hoses

These functions are dealt with in the cutting machine

and face services sections.

http://www.mech.uq.edu.au/pgthesis/WAUGE-David.pdf

- a thesis on modeling loads and tensions in AFC chains

IngentaConnect

Power requirement prediction for armoured face conveyors – method of

calculating AFC power requirements – not free information, to be

purchased