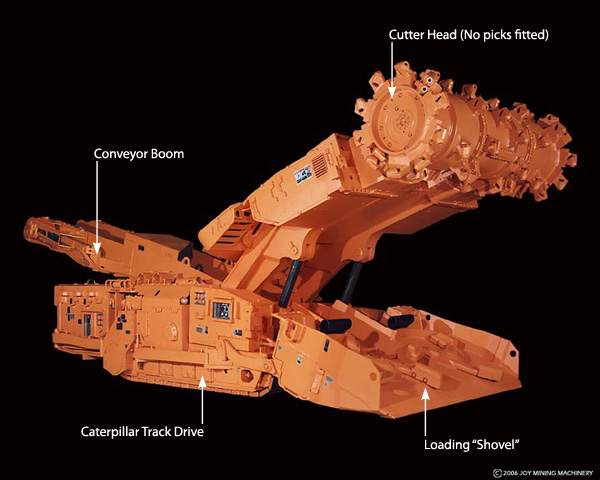

Continuous miners

Though there are many variations in design, continuous

miners mostly consist of five main elements:

-

A central body to carry all other

components mounted on some type of drive mechanism to provide mobility (most

commonly caterpillar tracks).

-

A "cutting head" usually rotating drum(s) and/or chains

with cutting picks attached

-

A loading mechanism to pick up cut coal and

deliver it into the central part of the machine

-

A conveying system, usually a chain

conveyor running in a steel trough from front to rear of the miner

-

A rear jib section capable of a degree of

vertical and horizontal movement to enable the coal to be delivered into a

transport or loaded at a desired point.

Some continuous miners (at one time almost all) could

not cut the full roadway width in one pass but had to be moved backwards and

forwards and from side to side in order to cut the full profile. This often

results in a very rough rib line (bad for stability and ventilation flow) and

delays the ability to install support into/under freshly exposed roof for a

period. The advantages of the ability to cut the full profile in one pass was

recognized early, but was not easy to achieve. Cutting forward in a straight

line could be readily accommodated, but it is necessary to be able to turn

corners, mostly at right angles, and to be able to retreat the cutting machine

from one roadway to relocate at frequent intervals. These factors have proved

major stumbling blocks to many developments. In machines which covered the full

face, steering in the vertical plane could also be a major difficulty.

The term "continuous" as applied to development

machines has been one of the biggest misnomers used for mining equipment

because, on development, they are usually anything but continuously cutting.

The main delays mostly occur while roof support is installed and often waiting

for shuttle cars to return from their discharge point for reloading. When

actually cutting, cutting rates are usually more than adequate, but when

averaged over a shift cutting rates are often poor and this is one of the

reasons many mines have difficulty developing at rates adequate to prevent long

delays on longwall production. As a result, development is an area receiving

major attention in recent times. Many of the difficulties have been overcome

and most modern continuous miners are "full face" machines. They also have roof

bolting equipment mounted on the miner in locations allowing roof bolts to be

installed reasonably close to the face.

The "ideal" continuous miner would:

-

Be able to cut the full face in one pass

-

Be easily moveable between locations

without dismantling parts

-

Be able to excavate right angle turns with

a minimum radius

-

Have roof and rib bolters fixed to the

machine in a location where each row of the designed support pattern can be

installed without moving the miner and be installed close to the cut face if

necessary

-

Have adequate space alongside to allow good

ventilation of the face area for efficient removal of gas and dust.

-

Allow strata supports to be safely

installed while coal cutting continues

Many of these ideals have been achieved to varying

degrees of satisfaction (the last being an area of minimal success), but

matching development rates with longwall retreat rates is still a major problem

for many mines. Increasing numbers of development units to attain longwall

continuity is expensive and provides extra strain on all other service

functions (personnel, ventilation, materials handling, power and water

supplies, gas drainage, etc, etc) and is not usually a satisfactory solution.